FAQ

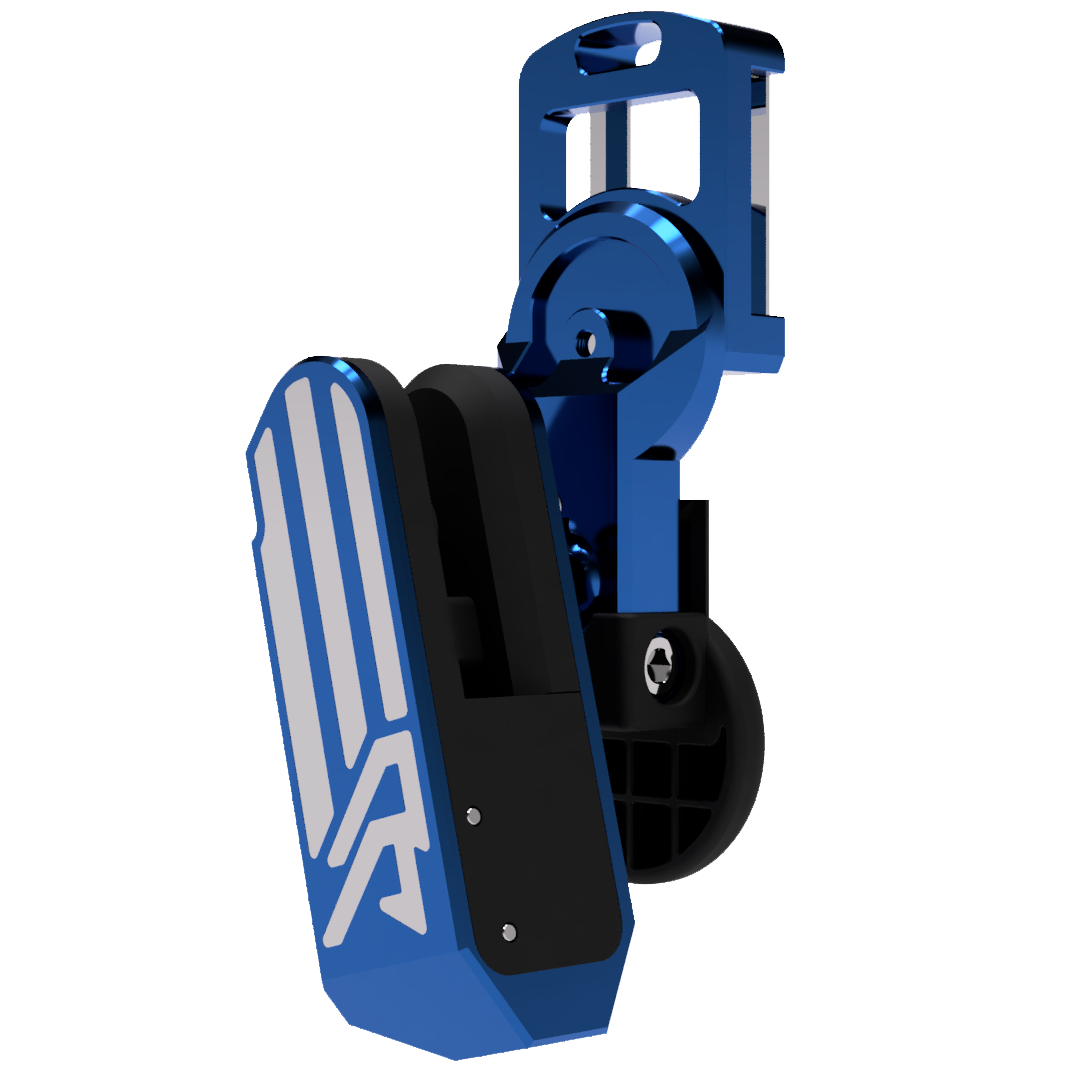

- Support System

- Race Master Holster

- Function

Q. What kinds of belts can I fit the RM holster to?

The belt holder is designed to accommodate belts up to 39mm (1.5”) wide. All belts in this category may be used. We have tried the holster on the DAA belts, CR speed, H&S and a few others. The retention plates at the back can be screwed down to grip tightly even thinner belts, so the holster can be held solidly. 2” belts cannot be used, unless you cut out a piece from the belt, narrowing it down to 1.5” at the point where the holster is placed.

Q. My holster seems to be a very tight fit on my DAA belt. Is this normal?

Yes, this is so. We believe that it is very important not to allow the holster to slide or rock on the belt, and since you fit it onto the belt only one time, we prefer a tight fit. Once positioned, the holster will not move at all. It seems some belts that are a little wider than others are a very tight fit, but we have not seen one that would not go. Use a rubber mallet if need be or lay the belt hanger on the floor (removed from the holster) and step on the belt to force it into place.

Q. It seems my tension adjustment knob is difficult to turn. Can something be done to improve this? (relates to 2013 and older Race Master models)

Yes. There are several things you can check and possibly modify if the tension screw is very tight to turn.

1. First, remove your insert and check the diameter of the hole in the aluminum pressure plate. If it is only 6mm, you can enlarge it, up to about 7.5mm. This often will reduce friction from the tension screw. The first holsters shipped had a 6mm hole in this plate, but we have since enlarged it.

2. It may be that the tension knob is rubbing against the aluminum housing. The hole in the aluminum housing can also be enlarged if need be. The first holsters shipped out with a 10.2mm hole, and we later enlarged them to 11mm.

3. Check to see that the square nut in the insert is positioned well and not causing the tension screw to stand at an angle. You can nudge the square nut back into place by applying pressure onto the screw head while it is seated in the nut.

4. A little oil in the nut can often also help – as there is friction between the nut and screw, seeing they are of very different materials.

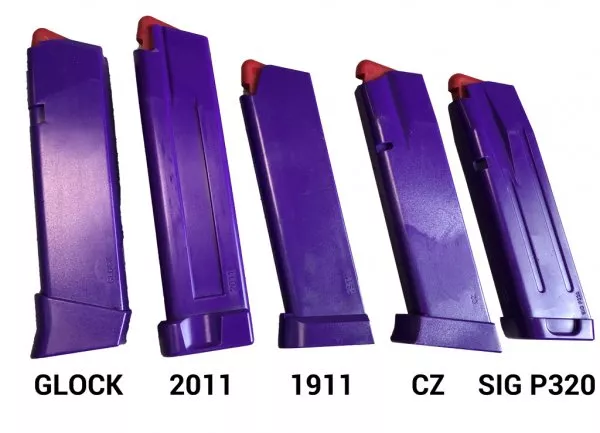

Q. My gun does not draw as smoothly as I would like. Can anything be done?

Yes. First, see if the gun releases easier when you remove the insert block from the aluminum housing. Assemble the tension screw, spring and pressure plate, outside the aluminum housing, and try to draw only from the insert. If this feels a lot better, that would indicate that the housing is slightly compressing the insert, which is then applying friction to your gun’s trigger guard. You can solve this by sanding off a little material from the outside of the insert block, either using a belt sander, or just a file or piece of sand paper laid flat. Remove material from the outside of the block – NOT the side with the safety installed in it.

Also check if the heads of the two pins for the safety assembly are sticking out. If they are, that can cause the plastic insert to be compressed more than it should inside the aluminum housing. Best solution here is to remove the pins (press them out from the inside) and enlarge the chamfer for the pin’s head, so that it can sink in to be completely flat. Use a 7-8mm drill bit held in your hand to enlarge the pins countersunk holes.

Caution! If you remove the top pin, the small spring and ball can fall out. The spring can jump out – so keep it pointed away from your face and wear safety glasses!

Another point to check is to see if the Slide Lock is sliding up and down freely inside the Insert Block. Remove the insert to check this, it should move freely. You can also pray in a little silicon to further decrease any friction between these parts.

Q. I find the large tension knob interferes with my hand on the draw. Is there a smaller option?

We plan to offer as an accessory a much smaller tension nub, which is not designed to be turned by hand, but rather with a screwdriver, and it does not jut out from the holster body hardly at all. A few shooters have asked for this, as they said that: a. they found the large knob interfered with their hand movement up the side of the holster when drawing and, b. the gun is so stable in the holster even when the tension is loose, that they do not feel they need to adjust the tension at all, so they prefer not to have the large knob.

We should have this accessory available in a few weeks.

Q. I find the safety lever rubs on my finger on the draw, is there a slimmer version?

There will be shortly. A few shooters mentioned they felt this serrated safety lever interfered with their draw, although most were happy with it. For those asking for it, we are going to offer a narrower safety level, and without the serrations.

Q. I think the safety level is a little too small. Is there a larger one available?

No. The reason it is in this dimension is that if we made it longer it would hit ones hand when in the up position, as you close your grip around the gun. A little practice will make this safety easy to reach. Also – since the gun is held so very well in the holster, it would be rare indeed to have to start a stage with the holster’s safety engaged. In 99% of cases you can confidently start the stage with the holster unlocked – and use the lock only between stages, as it is primarily intended to be used.

Q. I feel the holster presses a little too much into my leg. Can something be done to improve on this?

We did consider adding a padding plate there, like the Safariland do, but since very few of the test shooters complained about this – we felt it was not necessary, and a shame to make the holster so much more bulky.

First, experiment with the position of the support rod – you can tilt it to the forward position where it attaches to the belt hanger – this helps to distance it from your leg for most shooters.

Another options is indeed to attach some kind of padding to the back of the holster, and yet a third possibility, although a little radical, and should be used as a last resort only, is to bend the support arm outwards a little. If you do so you will most likely see a little damage to the anodizing, but it will do the trick.

Also keep in mind that using a good and very stiff belt will carry the weight of the holster and help to prevent it from pressing on your leg.

Q. I really would like more range of adjustment in the ball joint socket, so I can tilt the holster more. Can this be done?

If you really feel you need more range, you can enlarge the hole in the ball joint housing, thereby allowing more range to the ball joint. First dismantle the holster, remove the ball joint housing, and drill the front hole bigger. You should not go above 9.5mm. you can also chamfer the front of this hole, which will allow more range.

.png)

.png)

.webp)