5 Aug 2023

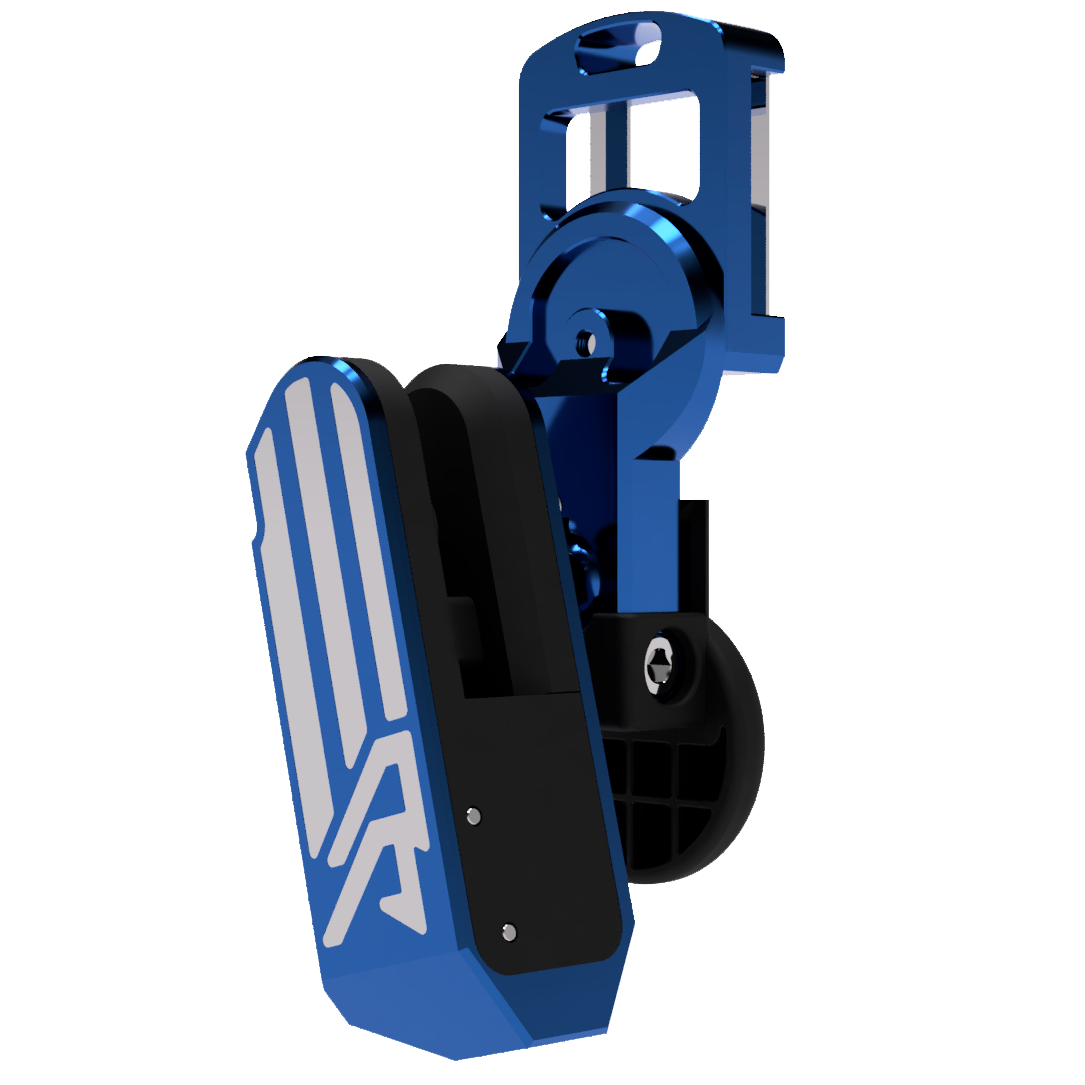

I'm new to reloading and I finally bought this after getting 2 squids during a match. This has increased the quality control and my processes of my reloads. I am now more confident that I don't accidentally miss or under/over charge my cases.

Dont wait till you have a reload issue like I did to get this. This is a lifesaver.

Dont wait till you have a reload issue like I did to get this. This is a lifesaver.

TIMOTHY JAVINES

9 Jul 2023

DAA Magnetic Powder Check 2.0 - it’s an awesome product, well designed and well made…..however as the new note indicates, it just doesn’t fit the Frankfort Arsenal X-10 press. The DA team was super helpful and Saul was awesome. We tried and after several emails with pictures back and forth, unfortunately it’s a no go on my X-10 and they issued me a refund. I’m sure it’s a great piece and DA is fantastic to work with.

Jeff Weir

3 Jul 2023

Not completely satisfied, i'm using 9mm brass with a fine spherical powder, everytime the brass ''sensor''-rod plumbs into the case there is a lot of powder splash. This on one hand makes the loads inconsistent and on the other hand i need to stop every 50 rounds to clean out my shell plate cause everything is filled up with powder...

A solution would be to make a caliber dependent ''cap" which prevents powder to spill out of the case...

A solution would be to make a caliber dependent ''cap" which prevents powder to spill out of the case...

Etienne THIJS

27 Jun 2023

I bought the powder check die was a little concerned with some of the reviews but so far my powder check die works with no issues, the check light and the sound alarm work like they should, as of yet I am not a big time reloader and still learning, I have mine installed on a Lee six pack pro 6000 progressive press, Iam also thinking of a bullet feeder system next.

Thanks Double Alpha

Earl F

Thanks Double Alpha

Earl F

Earl Forthun

3 Jun 2023

IMHO the electronic powder check is a must safety component when reloading on a progressive press. Even with the alarm, I also watch the magnet index into position at each press stroked as part of my loading cadence. This is an absolutely key tool to prevent squibs or overcharged loads.

Bradley Bonnette

28 May 2023

This is a well build product. It has a wide range of sensitivity, meaning you can adjust it down to a few grams of gun powder or set it just about where you need an alarm. We purchased 3 of these units. We have them set for over charge condition. Our units alarm at .5 grams of over charge and do a great job for us. We only make pistol ammunition. Great product.

Terrence Osman

.png)

.webp)